PVC/PVG Solid Woven Belt

Applications & Features:

- Especially suitable for material conveying at inflammable of underground coal mines.

- The fabric is high in strength, with low elongation, light carcass, shock resistant, anti-tear and good in trough ability.

PVC Solid Woven Conveyor Belt:

- Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

- Cover thickness can be from 0.5 to 4 mm.

Nitrile Covered PVG type:

- Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 8 mm.

- Resistance to wetness, slip, low temperature and wear resistance of the belt.

Standards: MT914, AS4606, BS3289, DIN22109

| Type | Grade | Tensile strength (N/mm) | Elongation at break(%) | Tear Strength(N) | Recommend thickness(mm) | ||

| Warp | Weft | Warp | Weft | ||||

| 680S | 4 | 680 | 265 | 15 | 18 | 1100 | 7.5 |

| 800S | 5 | 800 | 280 | 1200 | 8 | ||

| 1000S | 6 | 1000 | 300 | 1200 | 8.5 | ||

| 1250S | 7 | 1250 | 350 | 1600 | 9 | ||

| 1400S | 8 | 1400 | 350 | 1600 | 9 | ||

| 1600S | 9 | 1600 | 400 | – | 9 | ||

| 1800S | 10 | 1800 | 400 | – | 9 | ||

| 2000S | 11 | 2000 | 400 | – | 9 | ||

| 2500S | 13 | 2500 | 450 | – | 9 | ||

| 2800S | 14 | 2800 | 450 | – | 9 | ||

| 3100S | 15 | 3100 | 450 | – | 9 | ||

| 3400S | 16 | 3400 | 450 | – | 9 | ||

Joints Method

1.SPLICED FINGER JOINTING

Conventional vulcanizing presser are used for this process, in conjunction with a variety of polymeric jointing material developed for maximum joint efficiency.

This type of splice enables good quality joints to be made with strengths approaching that of the original belts.

2. MECHANICAL FASTENERS

The thick, high textile content of the solid-woven carcass, combined with the superior PVC impregnation produced by unique process, gives excellent fastener holding properties.

A wide range of fasteners including Mato, Goro, Flexco and Titan are suitable for use with Mechanical fasteners.

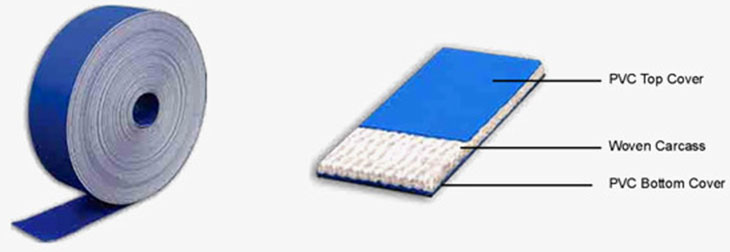

PVC solid woven belt

FEATURES

PVC solid woven elevator belt has

- durable tight woven polyester carcass that is co-extruded with a blue PVC covering both top and bottom. No delamination occurs under normal operating conditions.

- better characteristics of resistance to oils and some solvents, wear resistance and mildew resistance.

- resist bolt pulling through which means a reliable and secure performance of the bucket to the belt.

- Flexibility allows for a smoother running along the elevator pulley. Not easy to off track.

- Fire resistance and anti-static properties of the PVC make this belt ideal for using in grain handling applications.

TECHNICAL SPECIFICATIONS

| Model | Color | Tensile Strength N/mm | Thickness (mm) | Elongation at Rated Load % | Recommended Minimum pulley Diameter(mm) |

| PVC230 | Blue | 500 | 5 | ≤1.0 | 300 |

| PVC400 | 700 | 6.2 | 400 | ||

| PVC520 | 900 | 7.8 | 500 | ||

| PVC640 | 1100 | 8.8 | 700 |