Nylon Core Transmmission Belt

I. Description:

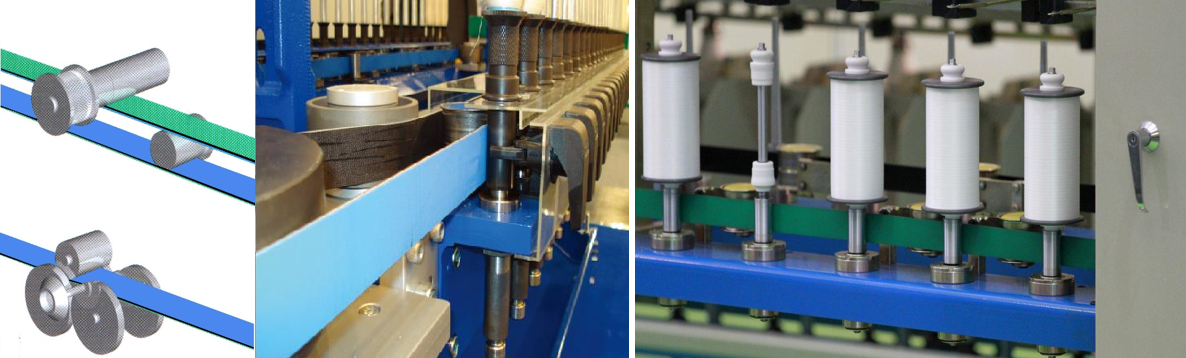

Using nylon core as tensile layer, the outer layer is abrasion -resistant rubber or leather, combining with high-strength polyamide fabric.

The belt is high strength and low elongation,good in flexing, smooth in transmission, Shock-absorbing, high friction,oil resistance,anti-static,

high efficiency in transferring.

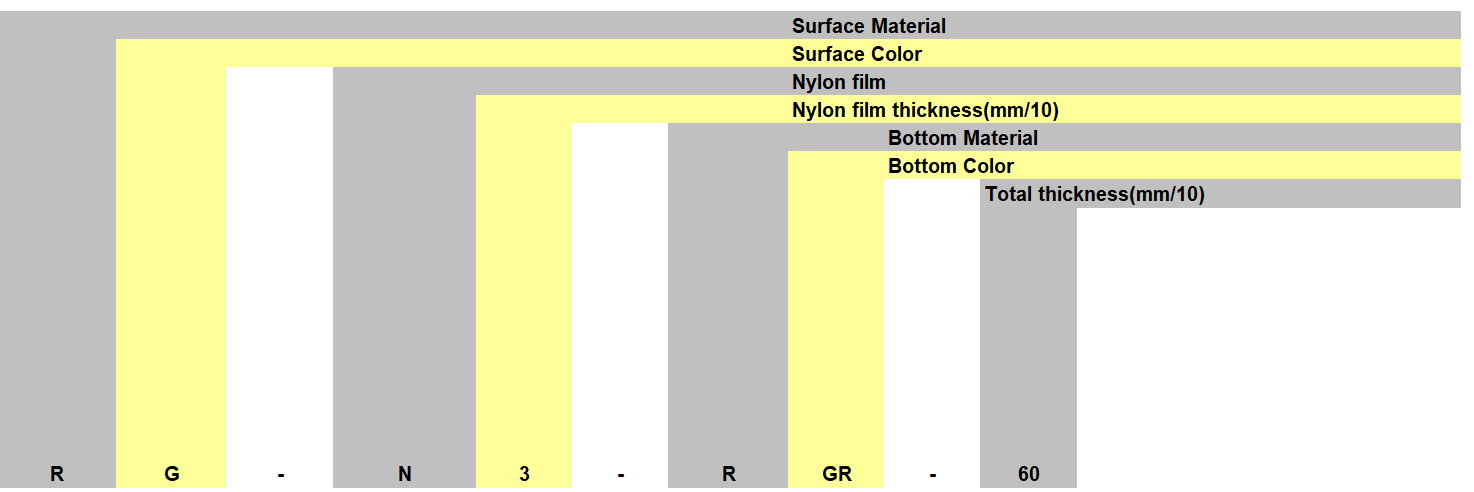

II. Code and Abbreviations:

Code of material:

- F polyamide fabric.

- R Rubber

- L Leather

- N Nylon film

Code of color:

- T natural/transparent

- G green

- W white

- B black

- GR grey

- R red

- BR brown

- P petrol

- BL blue

- O orange

The tensile body-nylon. The surface-abrasive rubber or leather. The middle layer-high-strength polyamide fabric.

It is advanced in high-strength, small-elongation, smooth-transmission, cushion and against-shock, high coefficient of friction, also excellent in resistance to greasy dirt and anti-static, good in transmission.

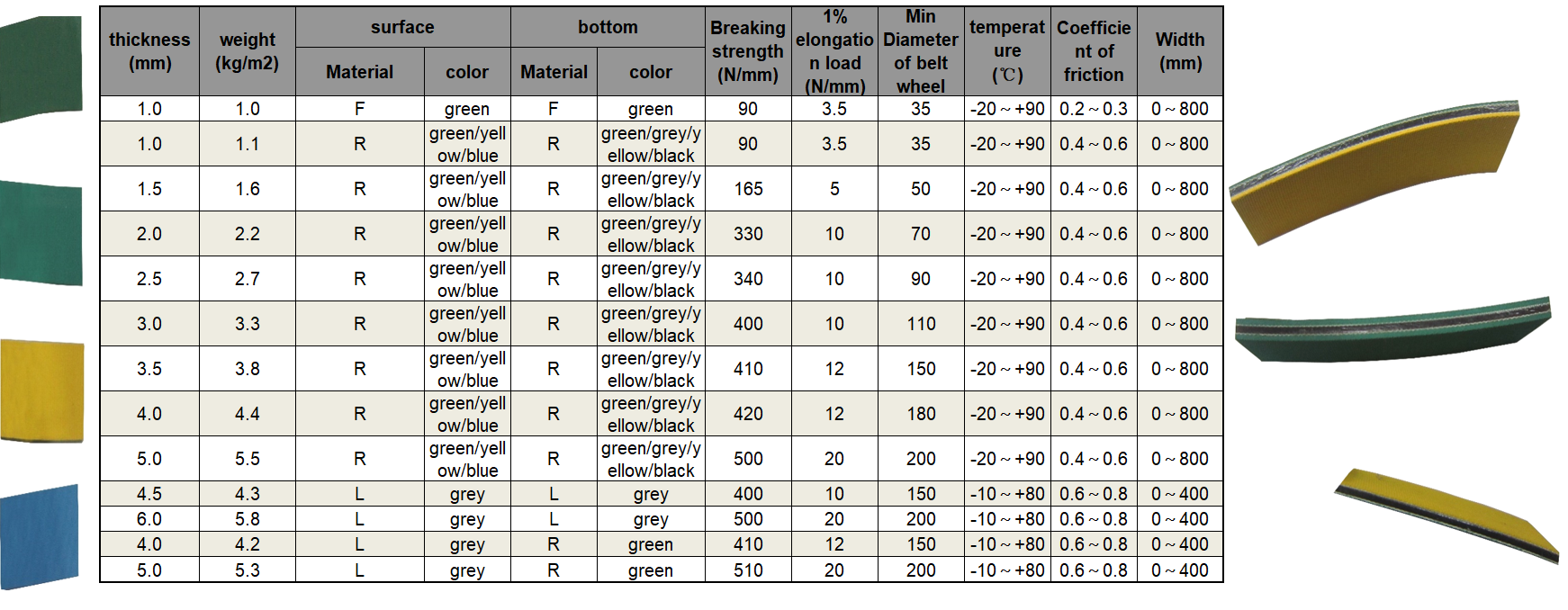

Breaking strength of nylon base≥ 3000 kgf/cm2

Breaking extensibility of nylon base≤ 25%

Elastic coefficient of nylon base≥ 1200 kgf/cm2

Abrasive resistance of rubber surface≤ 0.05cm3/1.61km

There are two kinds of leather. One is head-layer leather, which the surface is smooth and compact. The other is second-layer leather, which is crude and loose after abrasive treatment on its surface.

You can choose different thickness of belt base according to different load conditions and different rubbers thickness on different rsing conditions.

The thickness of nylon core: 0.3-1.5mm. Also processing special belts according to you demands.

III. Technical data:

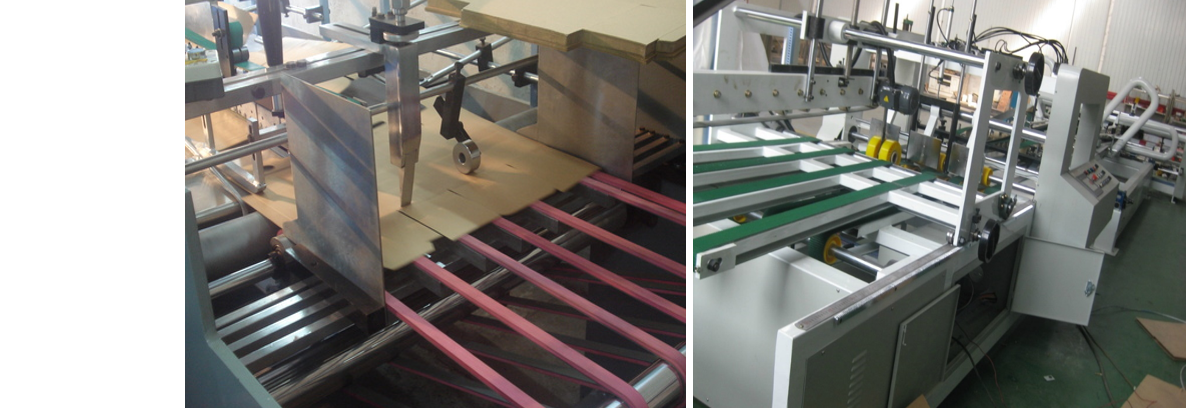

VI. Application

Box folder gluer machine

Textile industry