IW Belt

IW Conveyor Belt

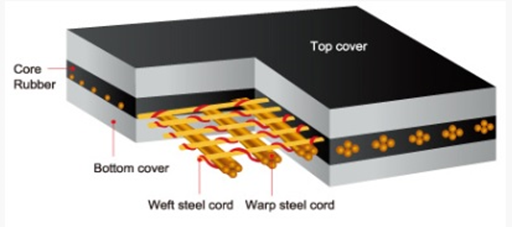

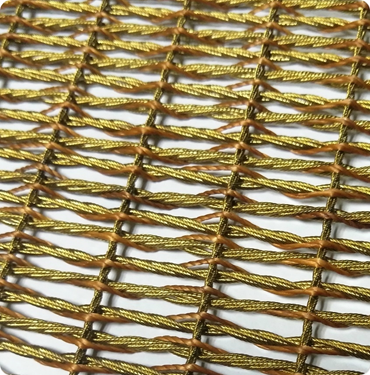

IW conveyor belt is constructed from high quality woven steel cord fabric with steel cord in longitudinal and transversal direction fixed together in 1 ply as carcass. It can be used for universal application because it delivers trough ability with a high impact resistance.

Product Features:

IW is appreciated for the superior qualities it offers for resistance to tear, resistance to perforation in applications with strong impacts, and the effect of high temperature from burning materials.

IW is utilized in special applications found in hard rock quarries, iron and steel industries and foundries.

IW is utilized for elevator belt applications requiring very high tensile strengths and yet minimal belt elongation.

Application in conveyors with small pulley diameters.

Type Selection:

IW Type

350 500 630 800 1000 1250 1400 1600

Technical Data:

| No. | Project content | unit | Strength Serial | tolerance | ||||||||

| 1 | Warp strength | N/mm | 350 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 0,+ | |

| 2 | Weft strength | N/mm | 95 | 95 | 95 | 130 | 130 | 180 | 180 | 180 | 0,+ | |

| 3 | Mass | Kg/m2 | 1.83 | 2.43 | 3.00 | 4.20 | 4.98 | 6.30 | 7.00 | 7.88 | ±2.5% | |

| 4 | Mesh thickness | mm | 3.0 | 3.0 | 3.0 | 4.3 | 4.3 | 5.8 | 5.8 | 5.8 | ±0.3 | |

| 5 | Warp cords |

Dia | mm | 1.98 | 1.98 | 1.98 | 2.82 | 2.82 | 3.86 | 3.86 | 3.86 | ±5.0% |

| Break load average | N | 3245 | 3245 | 3245 | 5890 | 5890 | 10098 | 10098 | 10098 | / | ||

| Break elongation | % | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | ±2.5 | ||

| Coating | Cu% | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 | 68.0 | 68.0 | 68.0 | ±2.5 | ||

| Zn% | 36.0 | 36.0 | 36.0 | 36.0 | 36.0 | 32.0 | 32.0 | 32.0 | ±2.5 | |||

| Pitch | mm | 8.30 | 5.80 | 4.60 | 6.65 | 5.37 | 7.02 | 6.23 | 5.48 | |||

| Density | Cords/m | 120 | 172 | 216 | 150 | 186 | 142 | 160 | 182 | ±2.0% | ||

| 6 | Weft cords |

Dia | mm | 1.50 | 1.50 | 1.50 | 2.09 | 2.09 | 2.39 | 2.39 | 2.39 | ±5.0% |

| Break load average | N | 1818 | 1818 | 1818 | 3073 | 3073 | 3998 | 3998 | 3998 | / | ||

| Break elongation | % | 7.3 | 7.3 | 7.3 | 7.3 | 7.3 | 7.3 | 7.3 | 7.3 | ±2.5 | ||

| Coating | Cu% | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 | ±2.5 | ||

| Zn% | 36.0 | 36.0 | 36.0 | 36.0 | 36.0 | 36.0 | 36.0 | 36.0 | ±2.5 | |||

| Pitch | mm | 17.5 | 17.5 | 17.5 | 20 | 20 | 20 | 20 | 20 | / | ||

| Density | Cords/m | 57 | 57 | 57 | 50 | 50 | 50 | 50 | 50 | ±5.0% | ||