Skirt Rubber

Skirting Rubber Description: Skirting rubber is a general purpose rubber used mainly in the mining industry as a side skirt on conveyor belt systems to prevent the materials falling down. It is available in full width slabs up to 2000 mm wide and also pre-cut skirting strips. STD 60 Duro A general purpose grade of natural rubber used for many quarrying and mining applications in dust and spillage control. Soft 35-40 Duro A softer grade natural rubber, with good tensile and elongations properties, it is…

Poly Sheet

Conveyor belt polyurethane skirting Polyurethane skirting is a specifically designed polyurethane sheet that is used as a sealing strip on conveyor system loading, transfer and discharge points to direct material onto the conveyor belt and reduce spillage. They are abrasion resistant and highly elastic for easy processing.The using life is 7 times of rubber skirting.

Capping Rubber

Polyurethane Capping/Capping rubber Polyurethane/rubber stringer bar capping are specifically designed extrusion products. To cover the stringer bars on vibrating screens to protect the steel stringer bars,supporting the screen cloths in vibrating screens. The polyurethane/rubber capping protects the top of the stringer bar and prevents the underside of the screen cloth from excessive wear and damage. Polyurethane Capping 1.Polyurethane Capping is made from a high-grade polyurethane compound, specifically designed to have excellent ozone, wear and impact resistance. 2.We base our recommendations for this type of…

Belt Cleaner

Primary PU Belt Cleaner(P-PU) Standard-Duty Primary PU belt cleaner(SD-P-PU): Applications: Belt Width: 450~2400 mm; Belt Speed: ≤3.5(m/s) Temperature: -40~90 ℃ Material Humidity: ≤15% Heavy-Duty Primary PU belt cleaner (HD-P-PU): Applications: Belt Width: 500~2000 mm; Belt Speed: >3.5(m/s) Temperature: -40~90 ℃ Material Humidity: ≤15% Secondary PU Belt Cleaner(S-PU) Standard-Duty Second PU belt cleaner (SD-S-PU): Applications: Belt Width: 450~2400 mm; Belt Speed: ≤3.5(m/s) Temperature: -40~90 ℃ Material Humidity: ≤15% Heavy-Duty Second PU belt cleaner (HD-S-PU): Applications: Belt Width: 500~2000 mm; Belt Speed: >3.5(m/s) Temperature: -40~90…

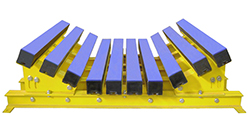

Impact Bar & Impact Bed

Impact Bar Impact bar is an important cushion part. Slow down the material on the conveyor belt and the impact damage, avoid sharp objects for tape tearing and scratches. Used in belt conveyor material guiding groove, blanking point below the belt. Outstanding capability to absorbing impact and low friction coefficient. Model: Specification (mm) Height (mm) Width (mm) Length (mm) 1220*100*50 50 100 1220 1220*100*75 75 100 1220 1220*100*100 100 100 1220 1400*100*50 50 100 1400 1400*100*75 75 100 1400 1400*100*100 100 100 1400 1524*100*50 50…

Pulley Lagging

Conveyor Pulleys can be provided with high quality lagging designed to ensure maximum belt and pulley life in tough applications. We could offer a full variety of lagging options including Plain lagging, Diamond Pulley Lagging, Ceramic Lagging and Replaceable Lagging. 1. Plain Pulley Lagging 2. Diamond Pulley Lagging Diamond Pulley Lagging has CN-bonding layer, to ensure higher bonding strength to pulley surface. Thickness: 8 mm, 10 mm, 12 mm, 15 mm, 20 mm, etc. 3. Ceramic Pulley Lagging 3.1 Ceramic Lagging with two rows 12…

Pulley

Conveyor Pulleys play an essential role in the performance and reliability of belt conveyor systems. Conveyor Pulleys are designed for use on belt conveyor systems as a means to drive, redirect, provide tension to, or help track the conveyor belt. Conveyor Pulleys are not designed for the same application intent as conveyor rollers. StandardA pulleys use highest quality materials in a production process with advanced technology. Our Quality Assurance system certified to ISO 9001:2000, lead our high quality products have reliable, long life performance in…